When that moment arrives, a red robotic cart will race across the polished concrete floor to pick it up. And from there, that bolt and its brethren will be on the fast track to their first flight.

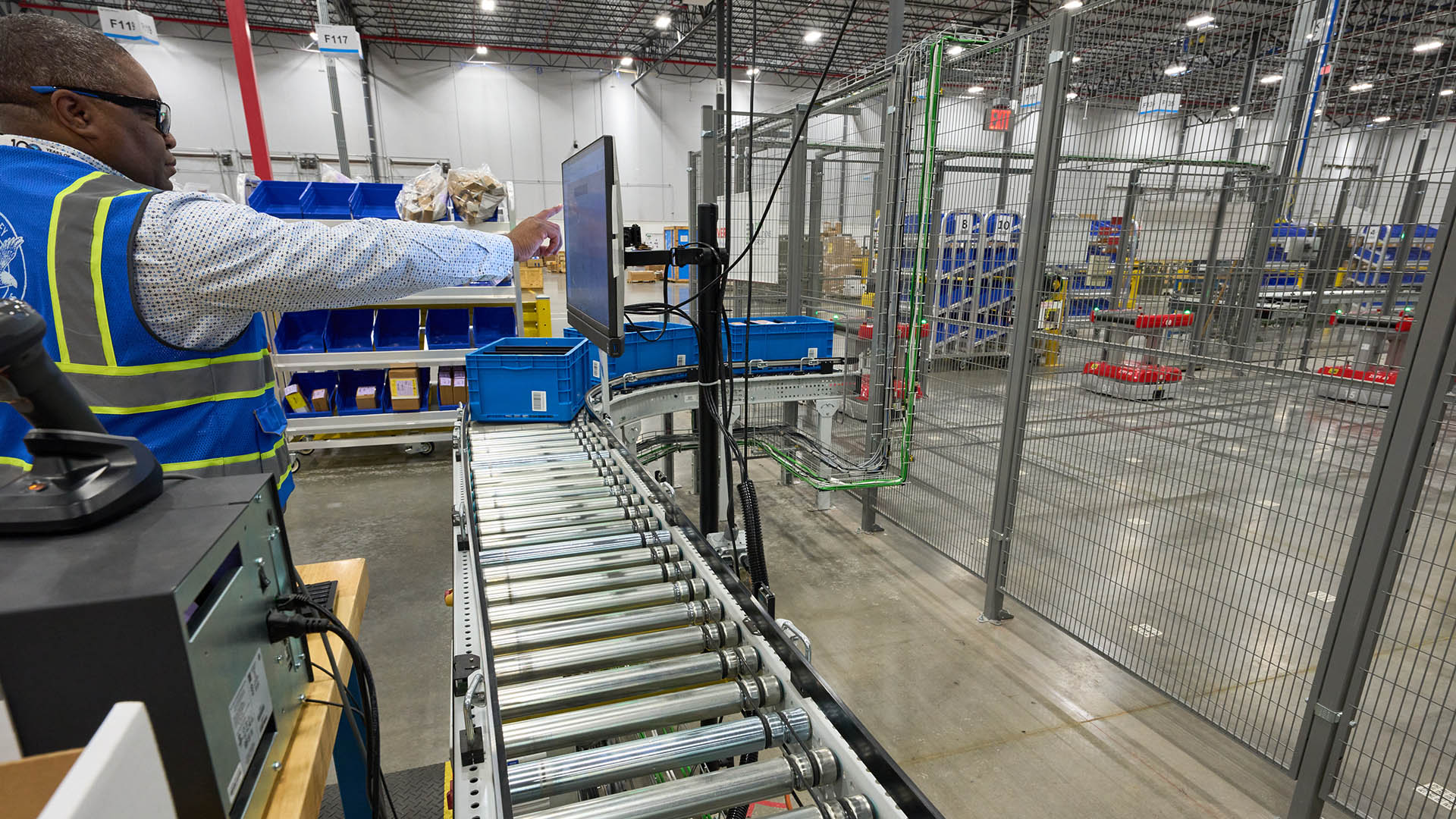

The storage area, the bins and the robotic carts are the linchpins of a new automated system Pratt & Whitney uses at its military engines logistics complex in Oklahoma City. That system drastically reduces downtime for military aircraft undergoing maintenance.

“We are really excited about it (this new system). Something that might’ve taken two days now takes two hours,” said Greg Treacy, the site lead in Oklahoma City and a vice president at Pratt & Whitney, an RTX business.

He was referring specifically to the process of locating replacement parts. But in a broader sense, he was also talking about using automation to complement the team’s efforts and improve overall performance at the site. Workers there inspect, repair or replace parts, and assemble “kits” of parts for Air Force mechanics, for multiple military engines including:

- The F135, which powers the F-35 fighter jet

- The F119, which powers the F-22 fighter jet

- The F117, which powers the C-17 Globemaster III transport aircraft

The site’s proximity to Tinker Air Force Base – a major maintenance, repair and overhaul (MRO) hub – reflects the close connection employees feel with the airmen, and the missions they support.

“Our partners on Tinker Air Force Base are just that. They’re our

partners, as we disassemble and assemble these engines,” Treacy said. “The

ability for us to be more efficient, to be faster, directly impacts their

ability to get an engine out the door to support the warfighter in the field

when that person needs it. So, our ability to have the right part at the right

time, at the right pace, is absolutely critical to the success of our entire

partnership. And that’s what this building allows us to support.”