Tier 1

Front-line workers discuss safety, quality, delivery and immediate issues in a quick stand-up.

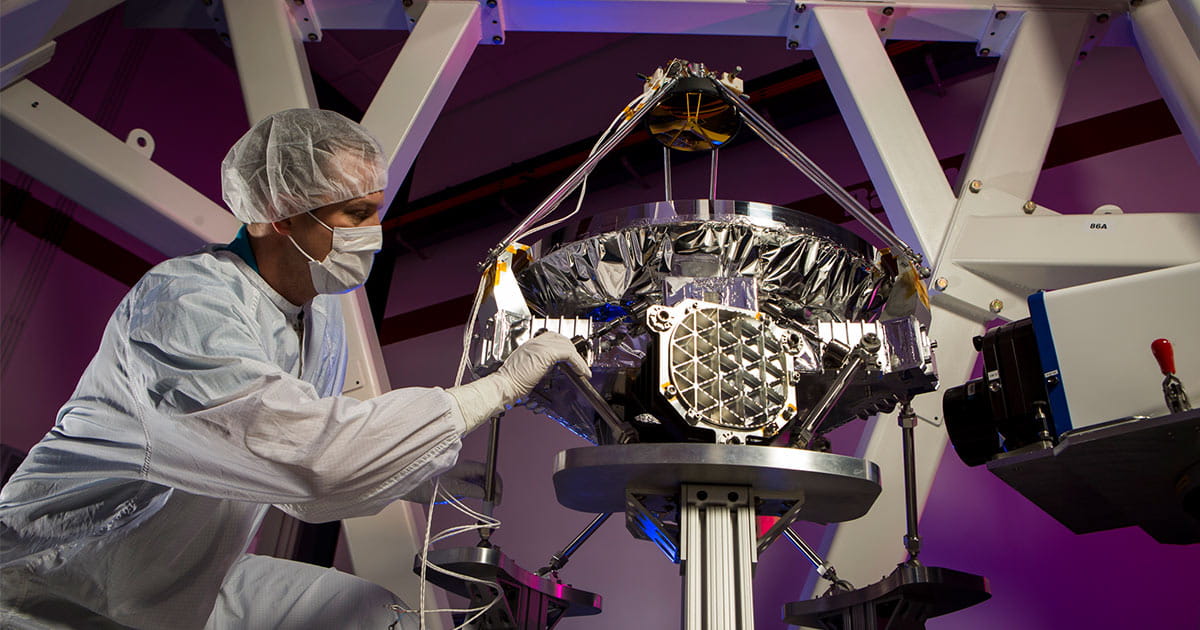

Printed circuit boards are the unsung heroes of aviation. Tucked away under metal or plastic panels, they control every inch of an aircraft’s electronics. They’re also remarkably complex – about the size of a standard sheet of paper, but with clusters of precisely arranged parts that measure in micrometers.

With that complexity comes a huge responsibility on those who inspect the boards before they leave the factory.

“Imagine ensuring 100 percent compliance with standards, on thousands of components. It’s almost impossible for the human eye alone,” said Jorge Vazquez, who helps lead a printed circuit board manufacturing site in Santa Isabel, Puerto Rico, for Collins Aerospace, an RTX business.

Which is why Collins is giving the human eye some help.

Automated optical inspection technology, including AI-enabled systems, has transformed the Santa Isabel site. Output is up 14%. The time it takes to inspect a circuit board is down from 30 minutes to 10. And escapes – the term for when parts that don't conform to standards make it out of the factory – have been cut in half.

AI-enabled systems came to Santa Isabel by way of RTX’s Connected Factory initiative, which demonstrates digital technologies at select sites known as “lighthouses,” then scales them across the company. That, in turn, is part of RTX’s broader data strategy, which connects the company’s systems, factories and products to speed design and development, reduce costs, improve quality and equip products with powerful new capabilities.

Inspecting a circuit board requires great care and skill. The components, many of them microscopic, can number in the thousands, and they must be put in exactly the right place, and in the right sequence.

Add in challenges with the supply chain, and the need to use substitute parts, and those problems of complexity multiply.

And that’s where AI steps in.

By the time a board reaches the final quality check, line workers have already overseen automated inspection at each stage of manufacturing. As a last step, the optical inspection system scans the assembled board, compares it to a perfectly assembled model, then alerts human inspectors to anything that appears incorrect.”AI is like having a tireless quality control expert that never blinks,” Vazquez said, describing the technology’s power to double-check the work of people. “It catches mistakes humans might overlook.”

With its speed, accuracy and adaptability, the system ensures circuit boards leave the factory ready to perform. And that’s the kind of outcome RTX is striving for not just in Puerto Rico, but at manufacturing sites around the world.

At the heart of the transformation is a collection of commercial software tools RTX is customizing and integrating into a proprietary AI and data platform.

Through those tools – whose capabilities include cloud computing, advanced analytics and support for software development – RTX can assess data from thousands of pieces of equipment in factories around the world, then identify bottlenecks, increase output and speed delivery.

The company’s CORE process improvement system has been pivotal. In 2025 alone, the site hosted about 50 CORE events, where colleagues collaborated to tackle specific problems like reducing defects, and finding ways to speed up manufacturing cycle times. Those projects turned up many areas for improvement, even in processes that appeared to work well.

“Our journey has shown us that all processes have wastes,” Vazquez said.

The process-improvement work builds upon years of efforts to transform operations in Santa Isabel. In 2019, the site introduced its “smart line,” which automated the production of printed circuit boards for commercial aircraft.

Then COVID hit, bringing new challenges – material shortages, supplier disruptions and a sudden drop in demand. Supply chain disruptions put stress on every part of operations – people, processes and materials – making it harder to maintain consistent quality.

But the site’s leaders couldn’t simply accept that.

“We had to rethink processes, streamline operations and make the most of the materials we had to overcome shortages and meet customer needs – everything had to run flawlessly,” Vazquez said.

The Santa Isabel site uses a daily CORE practice called tiered accountability to solve problems quickly and keep everyone working toward the same goals. Here’s how it works:

Front-line workers discuss safety, quality, delivery and immediate issues in a quick stand-up.

Supervisors huddle to address issues that couldn’t be resolved at Tier 1.

Functional teams address operational priorities and support problem-solving.

Leaders meet in the CORE control room to oversee operations and resolve issues escalated from lower tiers.

The site’s CORE control room is the central hub for operational excellence, and a key part of the RTX Connected Factory vision. Each day, senior leaders convene to review safety, people, quality, delivery and cost, analyzing risks from the past 24 hours and planning actions for the next. For example, in quality, they evaluate the number of defects found and discuss corrective actions.

Tiered accountability is the backbone of a real-time alert system called the Andon Visual Management System – one of the technologies the site is proving out for the benefit of others.

The system uses color-coded signals to show which factory processes are going well, which are at risk and which are behind or otherwise not working. Alerts that require intervention escalate automatically if no action is taken within a certain timeframe.

The result: Quick responses, reduced downtime and consistency in production.

“The issues don’t just disappear – they’re addressed, and operators trust the process when they see their Andon get noticed, acted on and get feedback,” said David Costas, digital director at Collins Aerospace in Puerto Rico.

And that’s what makes the system so effective.

“What fascinates me most about the journey is how it leads to solving problems you once sensed but couldn’t tackle,” Costas said.

Part of the problem was timeliness. Previously, for example, teams would track Monday’s performance metrics on paper and discuss them in a daily meeting – on Tuesday. So if production was off by 5%, the best they could have done was investigate and try to keep the problem from recurring.

Today, teams can intervene immediately, with detailed information that includes the part numbers involved, and possible underlying causes.

“We shifted from just reporting the news to driving actions to improve those matters,” Costas said.

The digital team partners with operations to bring these innovations to life. Both agree that success requires trust, follow-through and a culture of continuous improvement.

“Finding change agents – those who see the value in technology and are eager to drive progress – makes all the difference,” Costas said.

And they don’t have to search far to find them.

“People here are very committed,” said Jose Flores, operations director at Collins Aerospace in Puerto Rico. “We are early adopters by nature.”

While the inspection and visual management tools roll out across RTX, the Santa Isabel site is preparing to test a new capability: Real-time location tracking for each of the 10,000 boards moving through the shop at any moment.

That’s a major improvement over the existing system, where operators clock in at 3 a.m. and spend hours scanning boards and transferring data into spreadsheets.

“We only get one snapshot a day,” Flores said. “Once material moves, I have no idea how fast until the next day.”

The process is slow, labor-intensive and susceptible to errors, with missed scans leading to lost boards and delayed decisions. But a capability known as Real-Time Location Service (RTLS) will change everything. Each board will receive a tag that requires no manual scanning and can report its status.

“Think of it like an AirTag,” Flores said.

With RTLS, managers can make faster, smarter decisions, improving workflows and efficiency across the board – literally.

Vazquez and his team speak about the improvements they’ve made with excitement and pride, but the real benefits go to Collins customers.

“Everything we do is for the customer. We are here to deliver products to our customer faster and with better quality – every time,” Vazquez said.

And their journey of continuous improvement is only beginning.

“The pandemic got us started on this journey to improve,” Vazquez said, “and now it’s about building a strong foundation to handle anything that comes our way – even hurricanes – so we can keep growing and moving forward.”